eefit依飛把「半服務、半零售」的經營模式引入商場服務市民的健康品牌,希望提供一種在「家樓下」的服務。查詢分店網絡

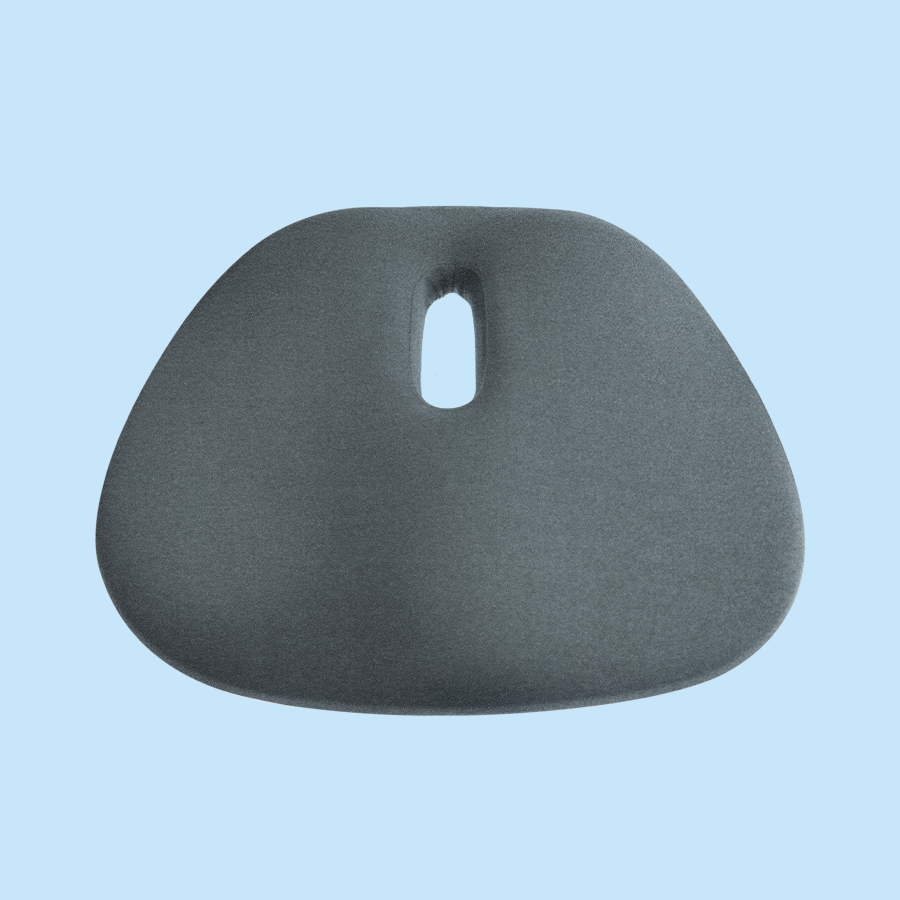

eefit Energy Cushion

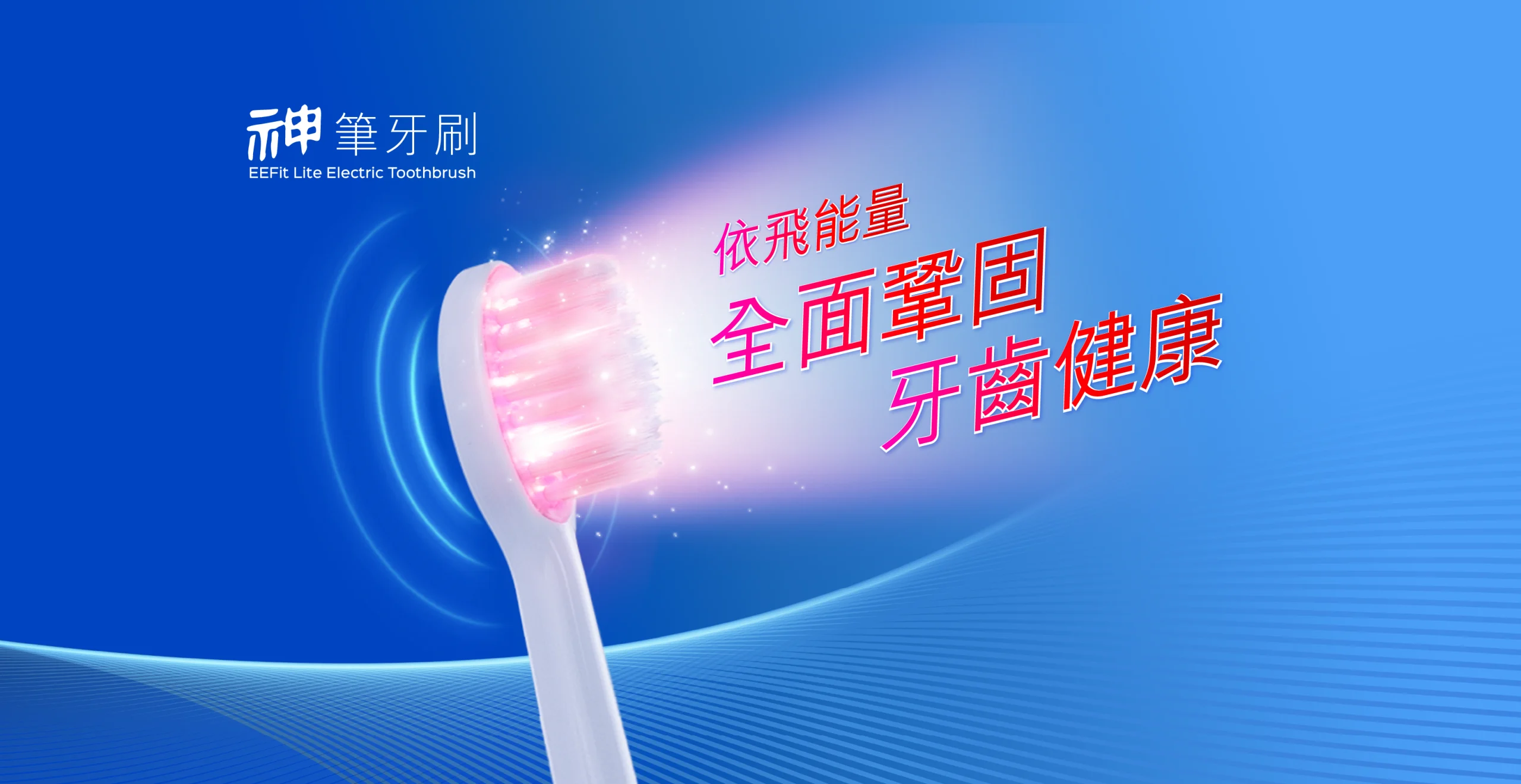

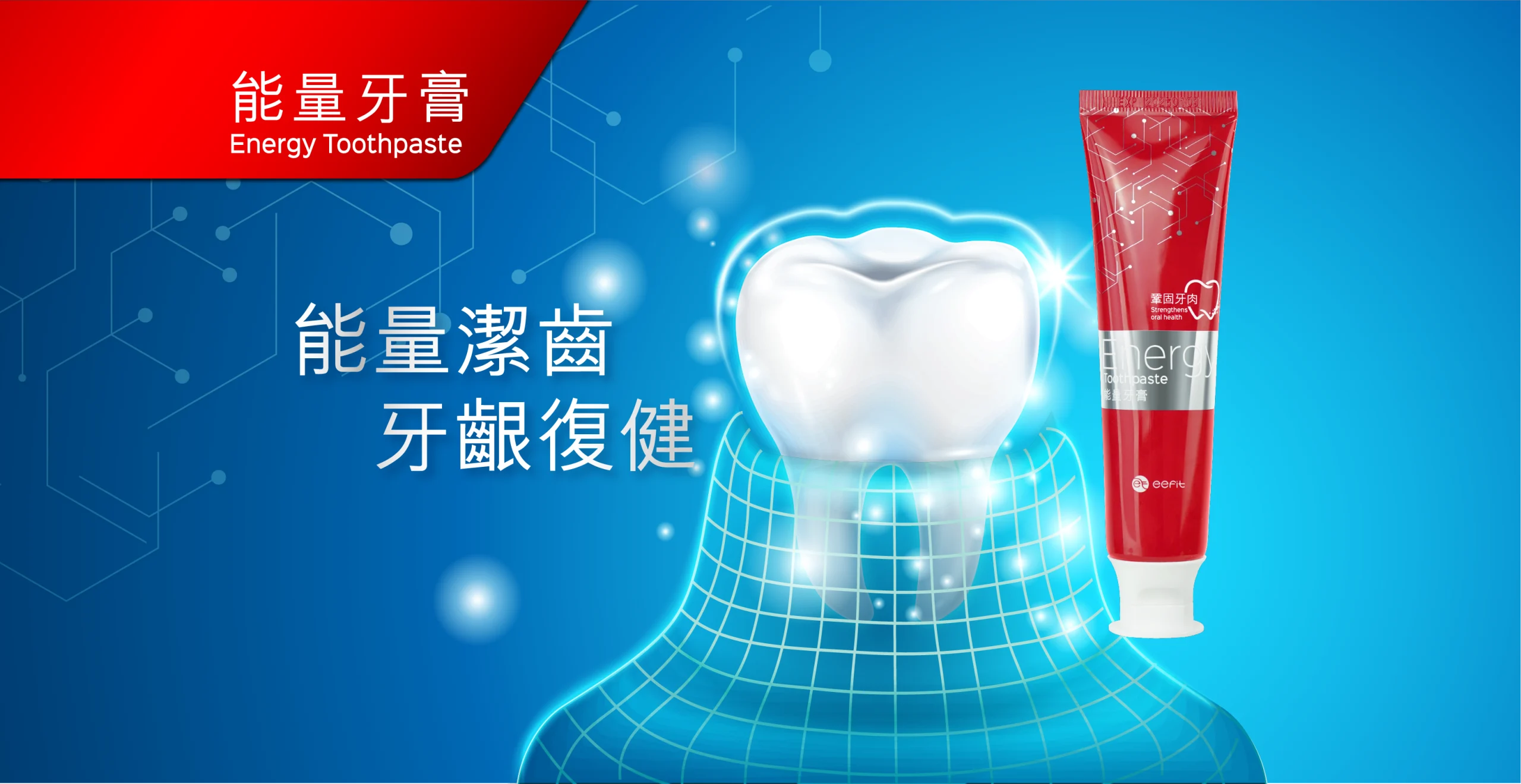

EEFit Lite Electric Toothbrush

Aqua Vitaliser

Energy-Cleansing Gel_Homepage-Hero_Desktop_ZH@2x-1-scaled

Energy-Lipstick_Homepage-Hero_Desktop_ZH@2x-1-scaled

Energy-Nail-Care_Homepage-Hero_Desktop_ZH@2x-1-scaled

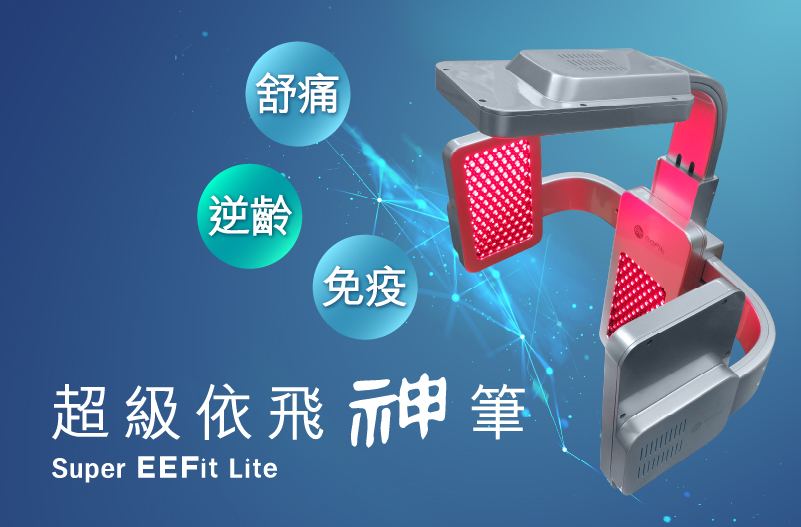

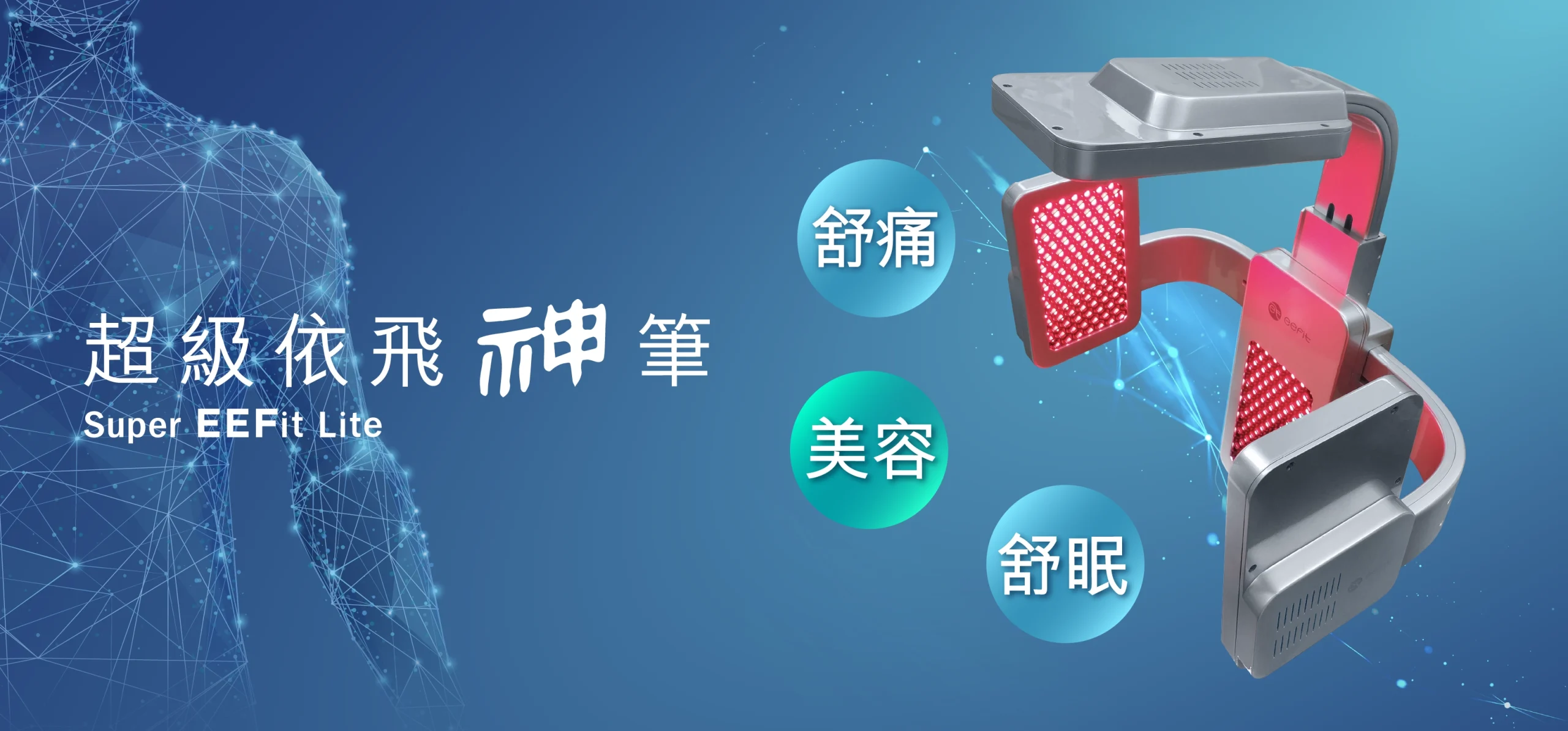

Hero-Banner_PC@2x-scaled

Hero-banner_PC_1@2x-1-scaled

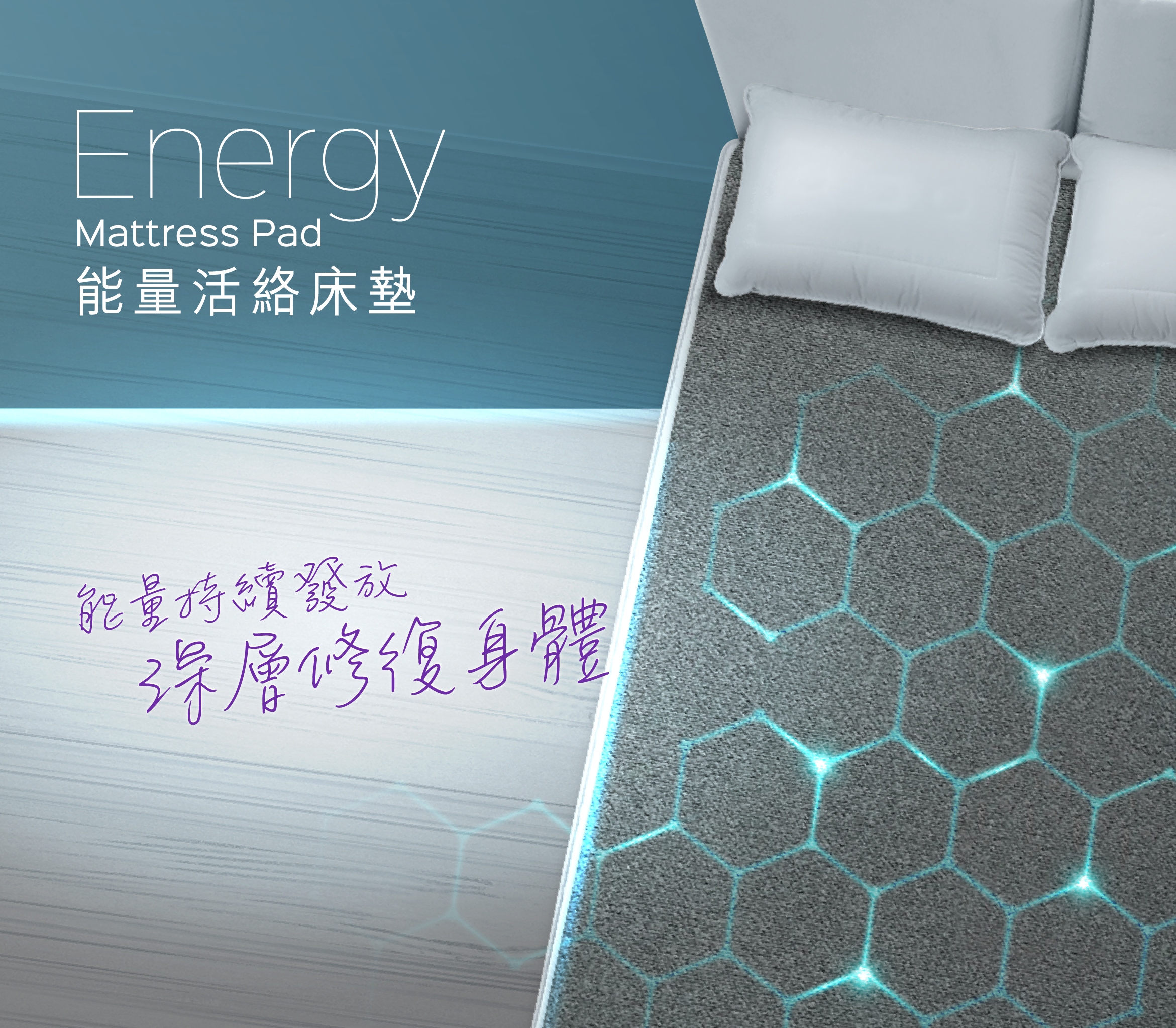

Energy-Mattress-Pad-Related_Homepage-Hero_Desktop_ZH-6@2x-scaled

Hero-banner_PC_ZH@2x-scaled

Energy-Velvety-Pillow-Sheet_Home-Hero_Desktop@2x-100-1-copy-scaled

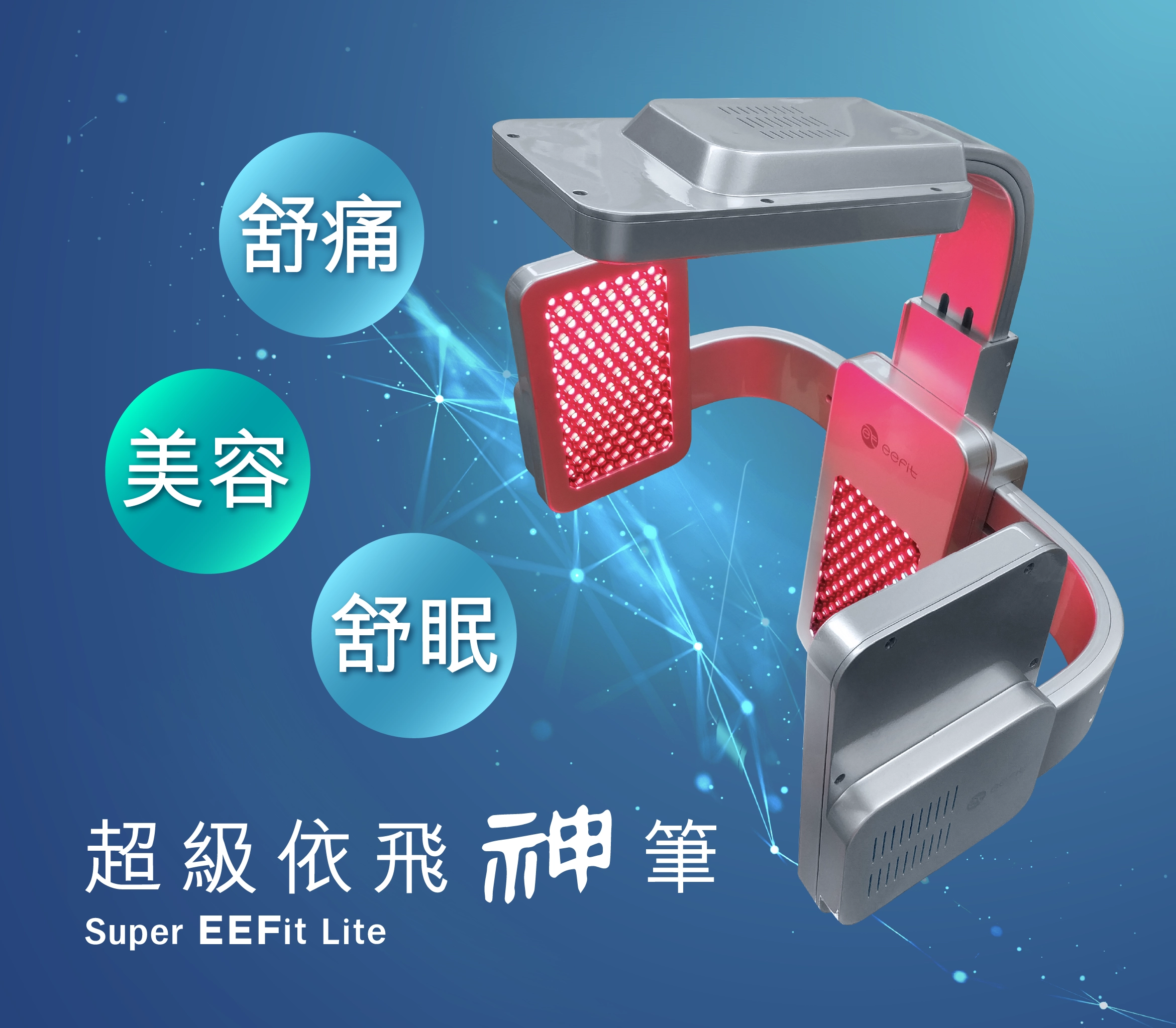

Ultra-Health-Light-Related_Homepage-Hero_Desktop@2x-100-1-scaled-copy

Ultra-Health-Light-Related_Homepage-Hero_Desktop@2x-100-1-scaled-copy

AquaenergyD-1-copy

eefit Energy Cushion

EEFit Lite Electric Toothbrush

Aqua vitaliser

Energy-Cleansing Gel_Homepage-Hero_Mobile_ZH@2x

Energy-Lipstick_Homepage-Hero_Mobile_ZH@2x

Energy-Nail-Care_Homepage-Hero_Mobile_ZH@2x

Hero-Banner_mobile@2x

Hero-banner_mobile_1@2x-1

Energy-Mattress-Pad-Related_Homepage-Hero_Mobile_ZH-@2x

Hero-banner_mobile_ZH@2x

Hero-Banner_mobile@2x

Ultra-Health-Light-Related_Homepage-Hero_Mobile@2x-100-1-copy

Ultra-Health-Light-Related_Homepage-Hero_Mobile@2x-100-1-copy

Hero-Banner_mobile@2x